Ceramics is often confused with Pottery and associated with humble objects like cups, bowls or flower pots. But in truth, it spans a wide variety of practices, materials and purposes: from high-performance engineering components to sculptural art installations. This article explores the seven main branches of Ceramics, each defined not just by the material itself, but by its function, intent, and context.

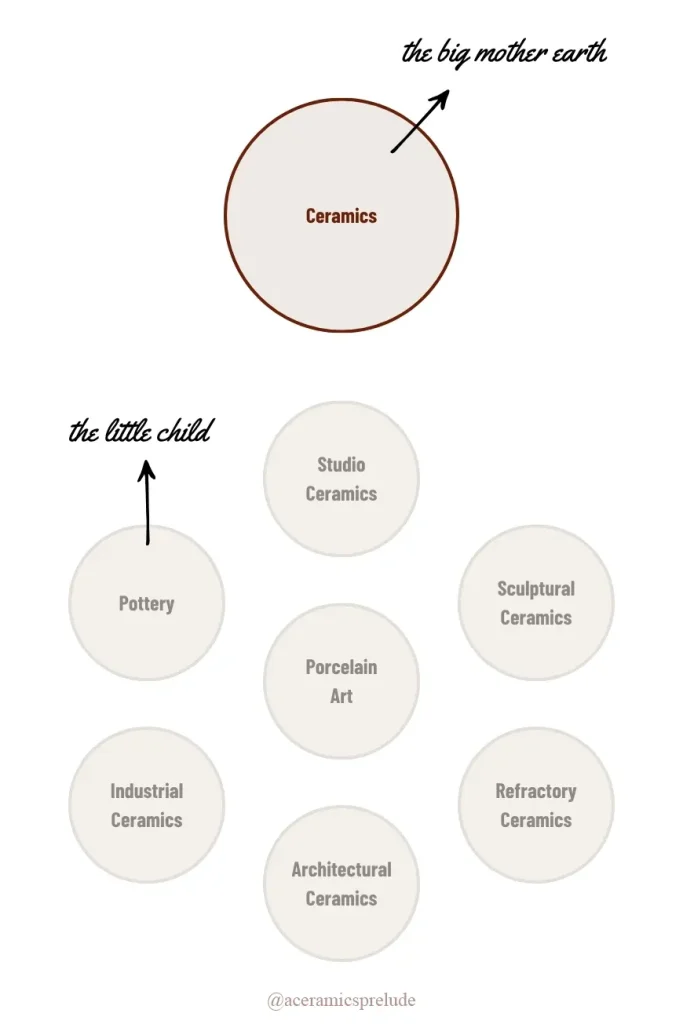

The Seven Dwarves of Ceramics: a visual overview

To better grasp the full landscape of Ceramics, it helps to visualise its major branches. Nevertheless, before diving into each branch, let’s take a step back because context is everything!

First of all, Pottery may be the one everyone knows – the friendly face of the family – but Ceramics is a much bigger household. Think of it as the Big Mother Earth and her seven very different children: some practical (Doc), some theatrical (Happy), some industrial (Grumpy and Sleepy), and one that absolutely refuses to be useful (Dopey). As an illustration, the diagram below offers a simple map of the full cast.

Spoiler: Pottery is just the youngest sibling.

If you’re still unsure about the difference between Ceramics and Pottery, start here.

Without further ado, here are the seven primary branches under the Ceramics umbrella (in no particular order):

- Pottery

- Studio Ceramics

- Sculptural Ceramics

- Porcelain Art

- Architectural Ceramics

- Industrial Ceramics

- Refractory Ceramics

Understanding how they relate clarifies why not all ceramics are pottery, and thus why not all clay ends up as tableware.

So now, let’s jump into each of these seven branches to explore what they are about, what they focus on, the materials and techniques they rely on – with illustrated examples along the way.

#1. Pottery

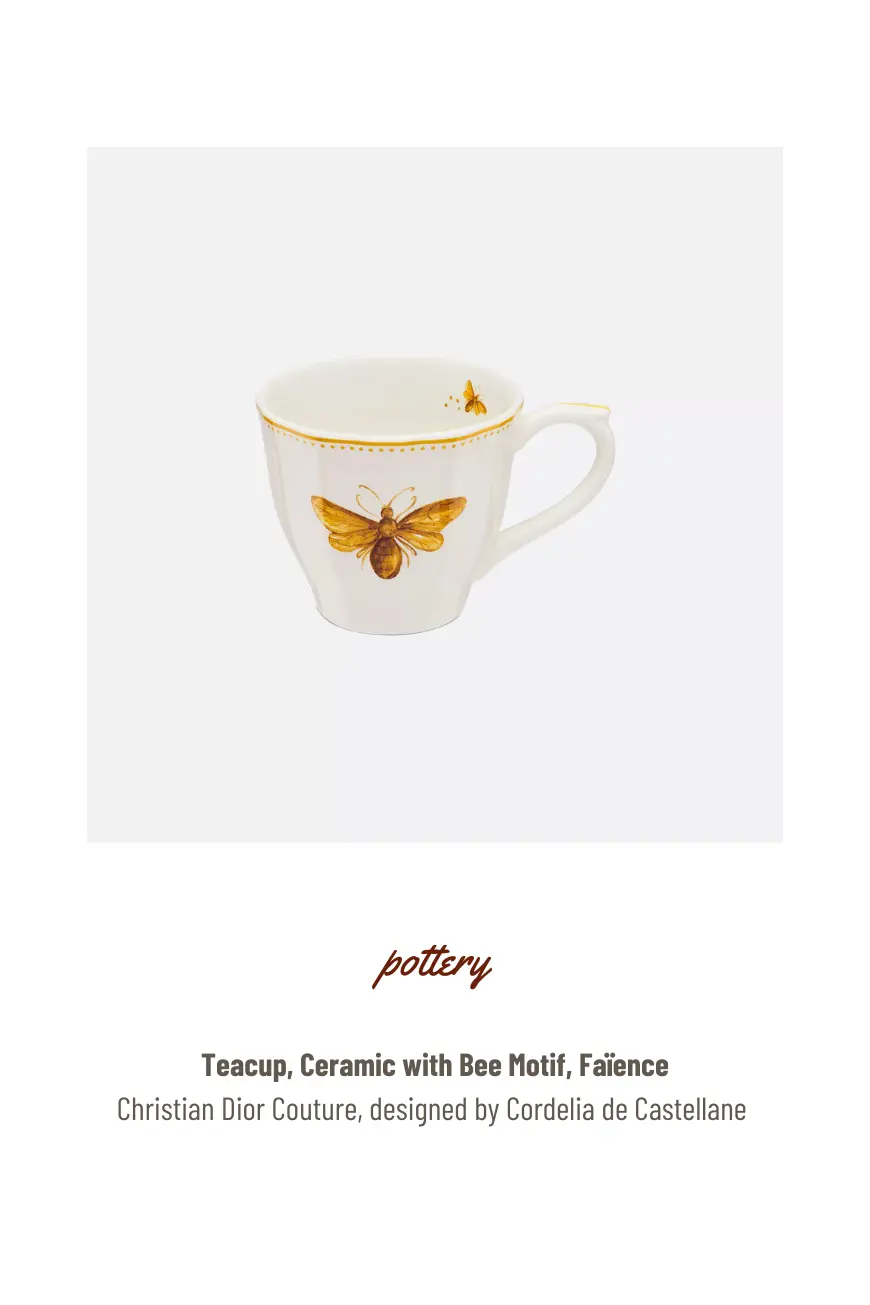

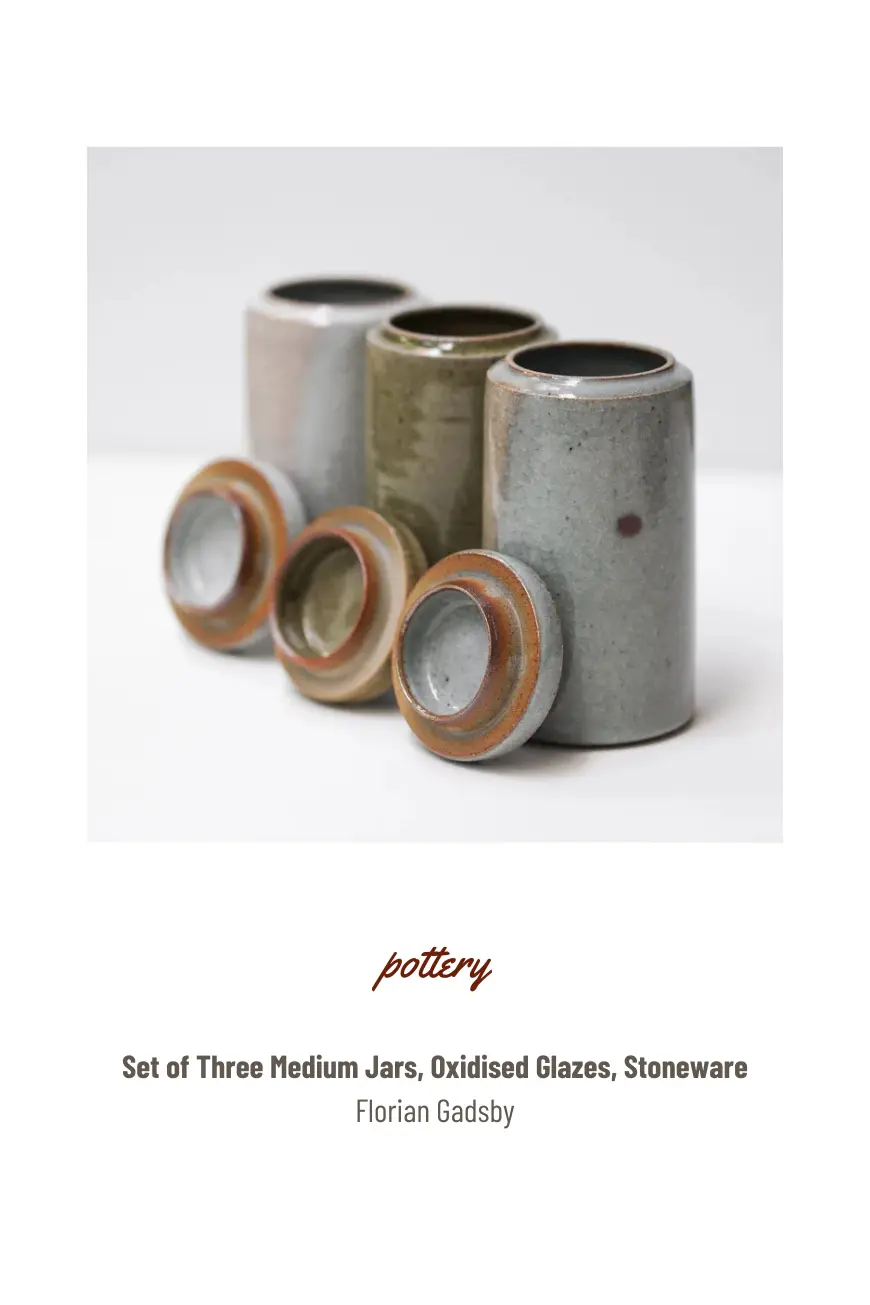

Pottery is probably the most recognised form of ceramics: the bowl on your table, the mug in your hand, the dish that holds your dinner. Its roots run deep in human history, yet it remains a living, evolving craft. Functional at its core, pottery is where clay meets daily life. Despite its utilitarian foundation, pottery can also be beautiful, expressive and highly refined.

Definition

Functional ceramic ware meant for daily use.

Focus

Utility – form that serves a purpose (eating, drinking, holding, pouring, storing, serving).

Typical materials

Earthenware, stoneware, porcelain (when used functionally).

Typical techniques

Wheel throwing, handbuilding (coiling, pinching, slab), trimming, glazing, firing (low to high temperature).

Examples

Here below some examples of splendid pottery made out of:

- faïence (earthenware), from Christian Dior Couture

- stoneware, by Florian Gadsby

- porcelain, from Hermès

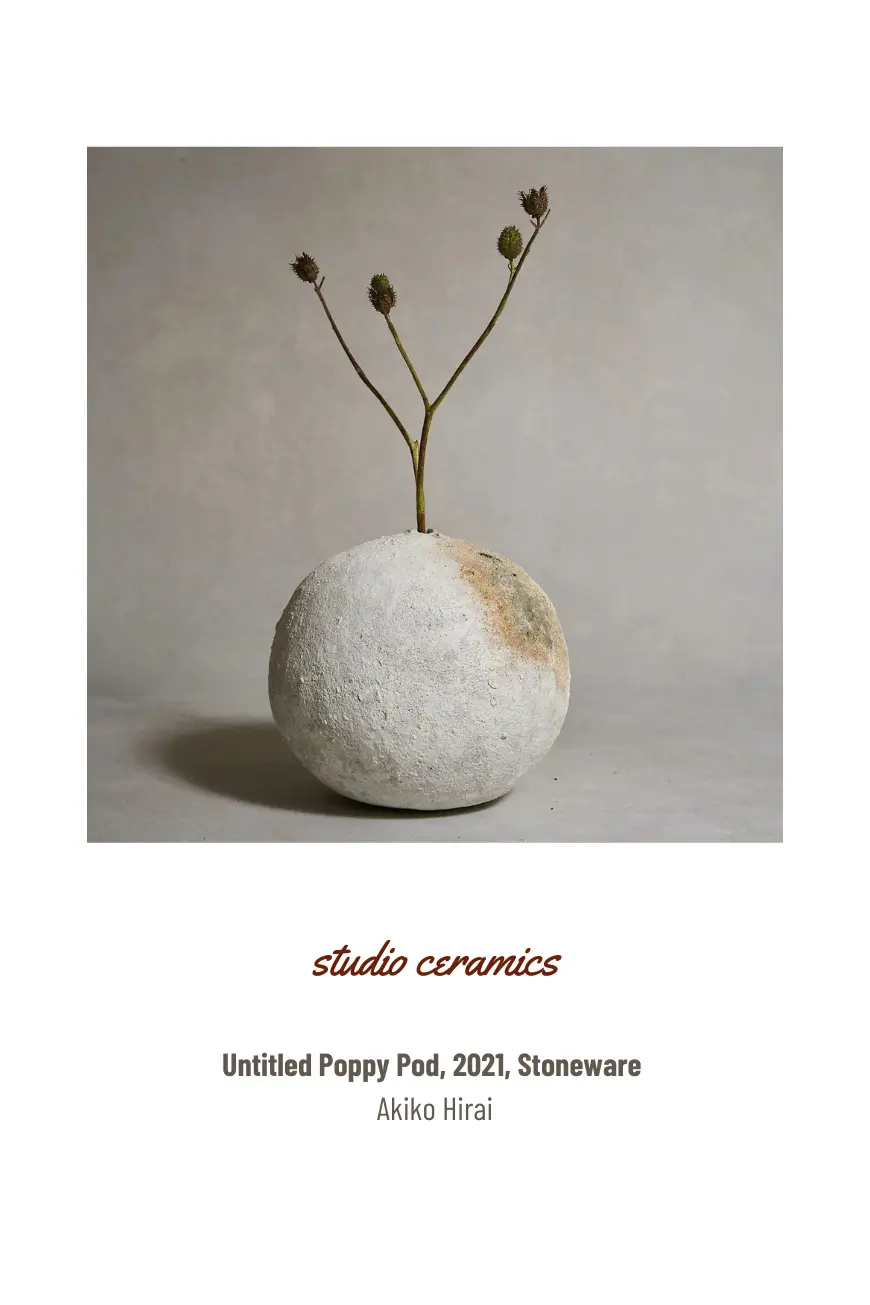

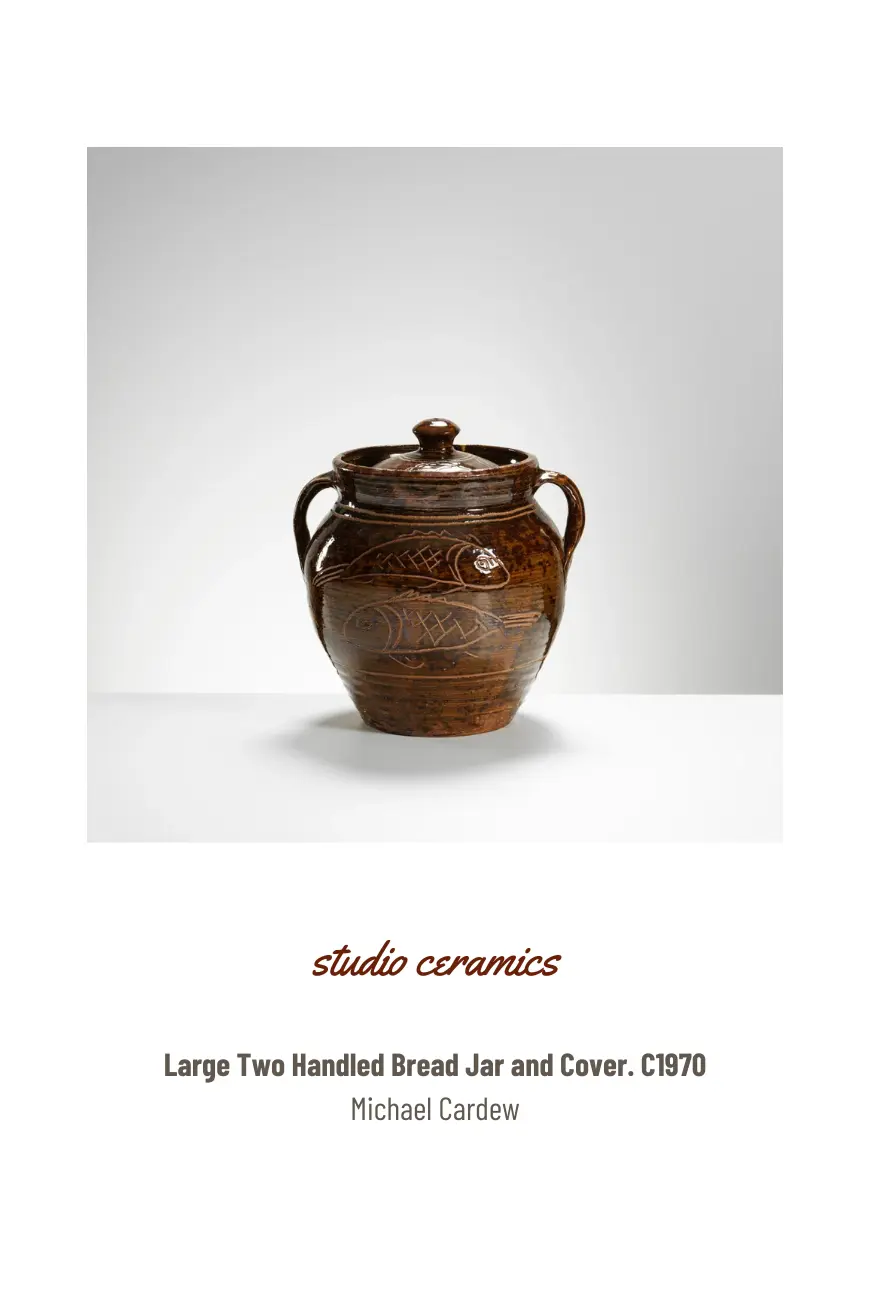

#2. Studio Ceramics

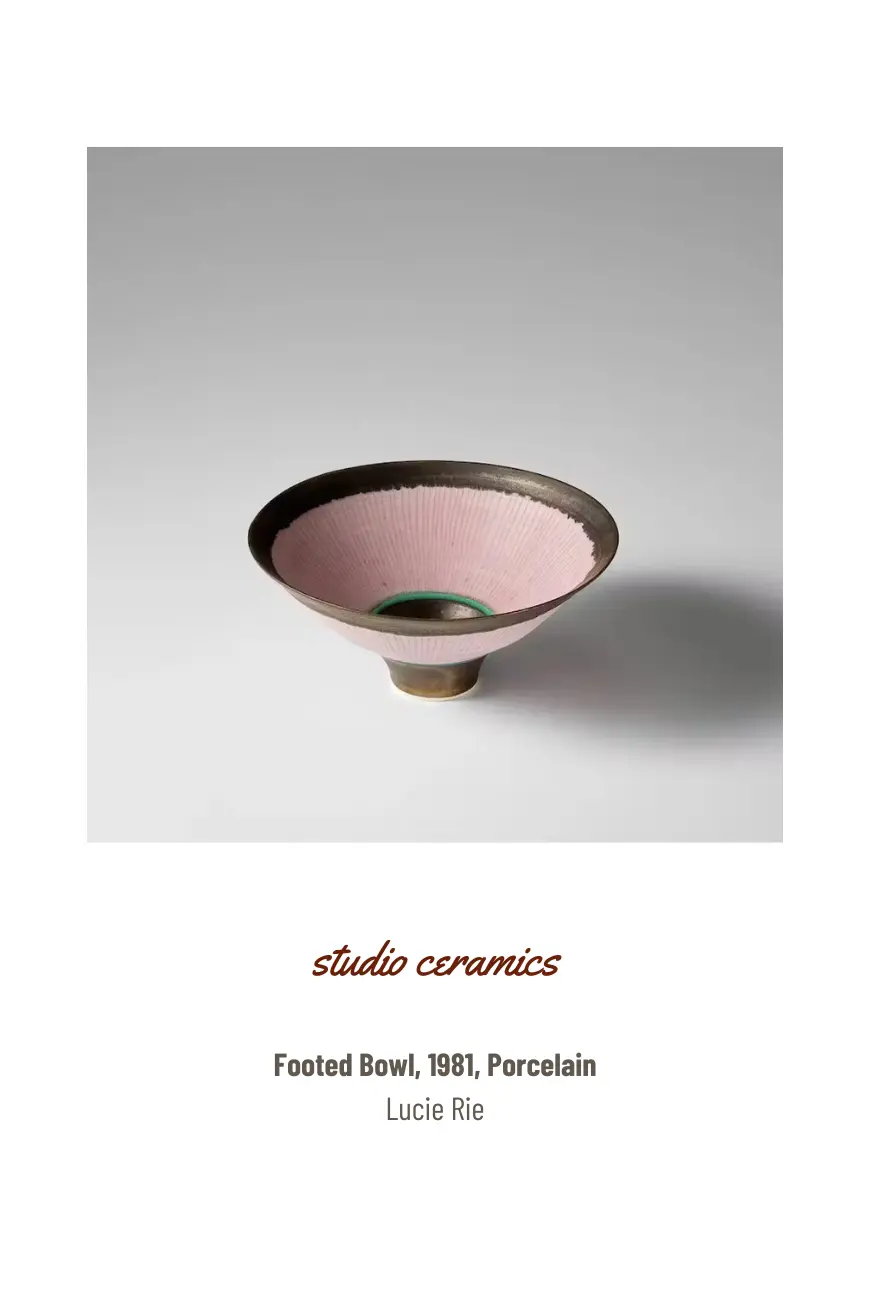

Studio Ceramics lives in the in-between: not quite industrial, not entirely sculptural. It’s where function meets personality, where the maker’s hand remains visible, and where the object holds more than just food or flowers. Often made in small batches or as unique pieces, studio ceramics values the conversation between form, intention and craft.

Definition

Individually crafted ceramic works made by artists in their own studios, often blending utility and artistic expression.

Focus

Personal vision, material sensitivity, limited production, often blurring the line between use and contemplation.

Typical materials

Earthenware, stoneware, porcelain (varies widely by artist).

Typical techniques

Wheel throwing, handbuilding, slip decoration, soda/salt firing, alternative glazes, sometimes experimental firings.

Examples

Here below some examples of signature studio ceramics created by:

- Lucie Rie, whose refined modernist forms and sgraffito glazes brought a sense of elegance, precision and quiet innovation to everyday vessels

- Akiko Hirai, who merges Japanese wabi-sabi aesthetics with British studio practice, creating textured vessels that balances rawness with subtle grace

- Michael Cardew, a pioneer of the studio pottery movement – his work is robust, earthy and deeply tied to the ideal of useful beauty

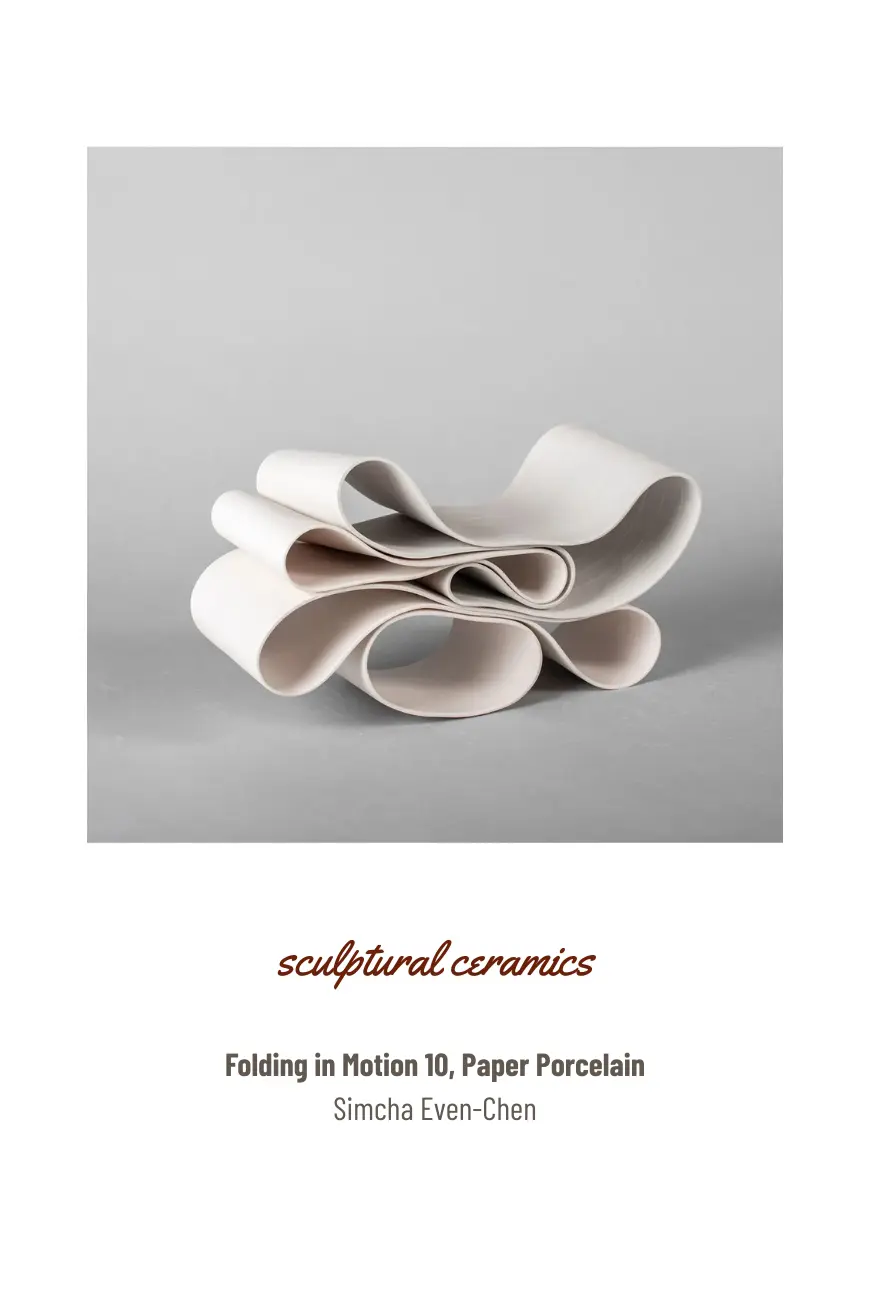

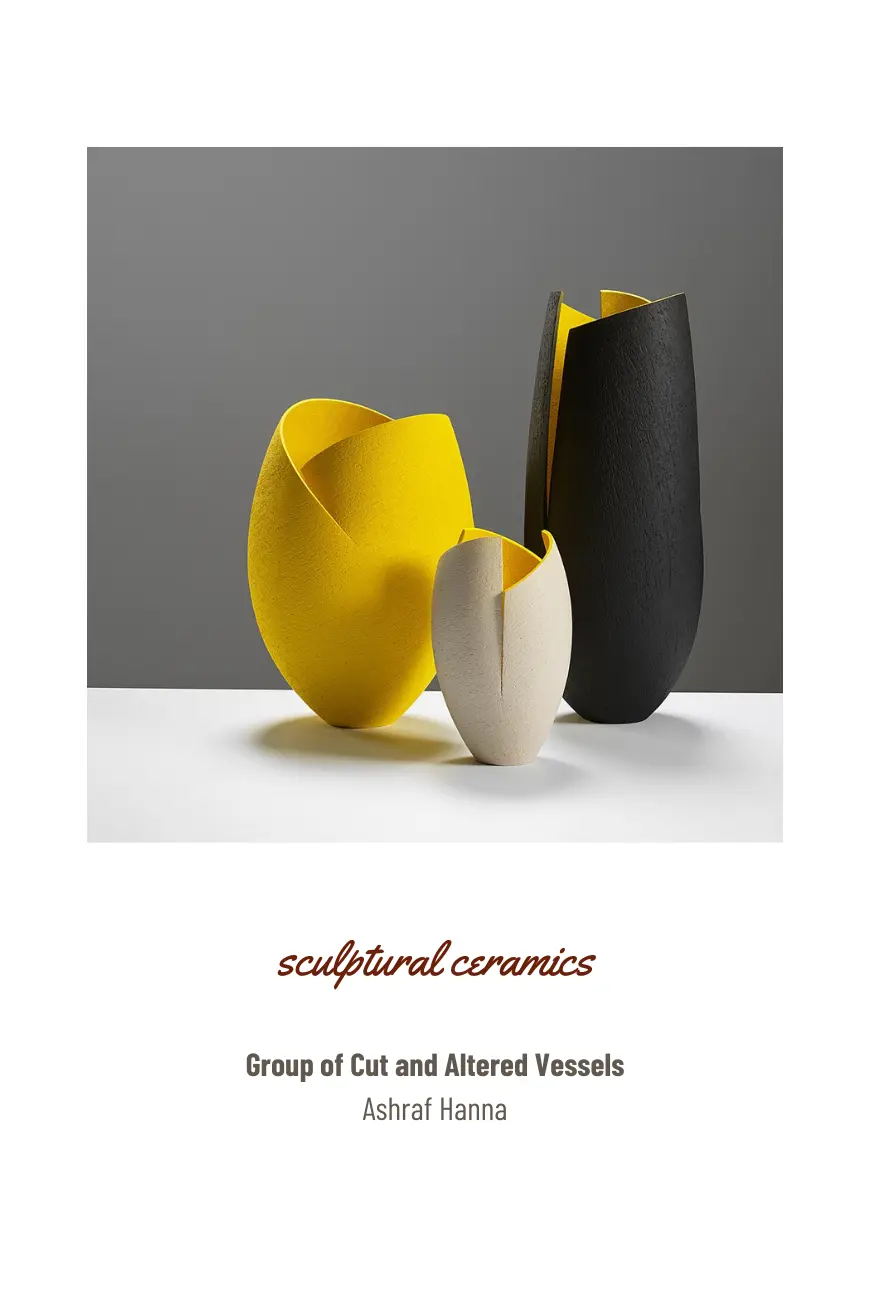

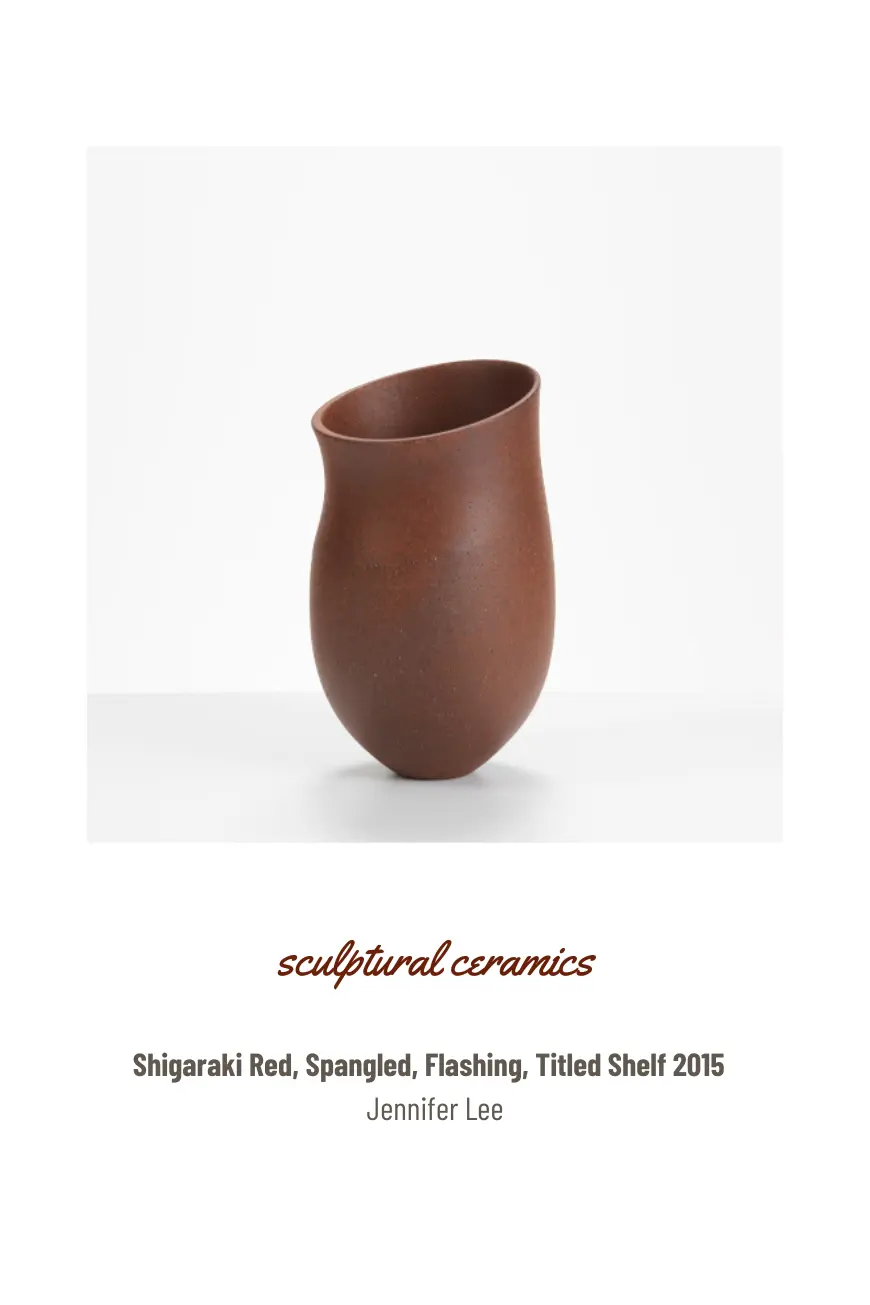

#3. Sculptural Ceramics

Sculptural Ceramics is significantly used by contemporary artists as a medium to express emotion, explore abstraction or question social norms. This branch dismisses the need for practicality and utility. As a result, it treats clay as a language, not a tool.

Definition

Non-functional ceramic works created as fine art and artistic expression, whether abstract, political, emotional or poetic.

Focus

Form, concept, narrative. In short, form over function.

Typical materials

Stoneware, porcelain, earthenware, paper clay, grogged clay.

Typical techniques

Handbuilding (slab, coil, carving), modelling, texturing, experimental firings, non-traditional finishes (oxides, stains, smoke firing).

Examples

Here below some beautiful examples of sculptural ceramics shaped by:

- Simcha Even-Chen, whose abstract sculptures explore balance, motion, and tension – often challenging the structural limits of porcelain

- Ashraf Hanna, who crafts minimalist, handbuilt forms with architectural clarity – his vessels become meditative studies in proportion and volume

- Jennifer Lee, whose asymmetrical, unglazed vessels are built slowly by hand, revealing quiet layers of colour, texture and geological calm

Each artist brings a distinct sensibility to form, surface and space.

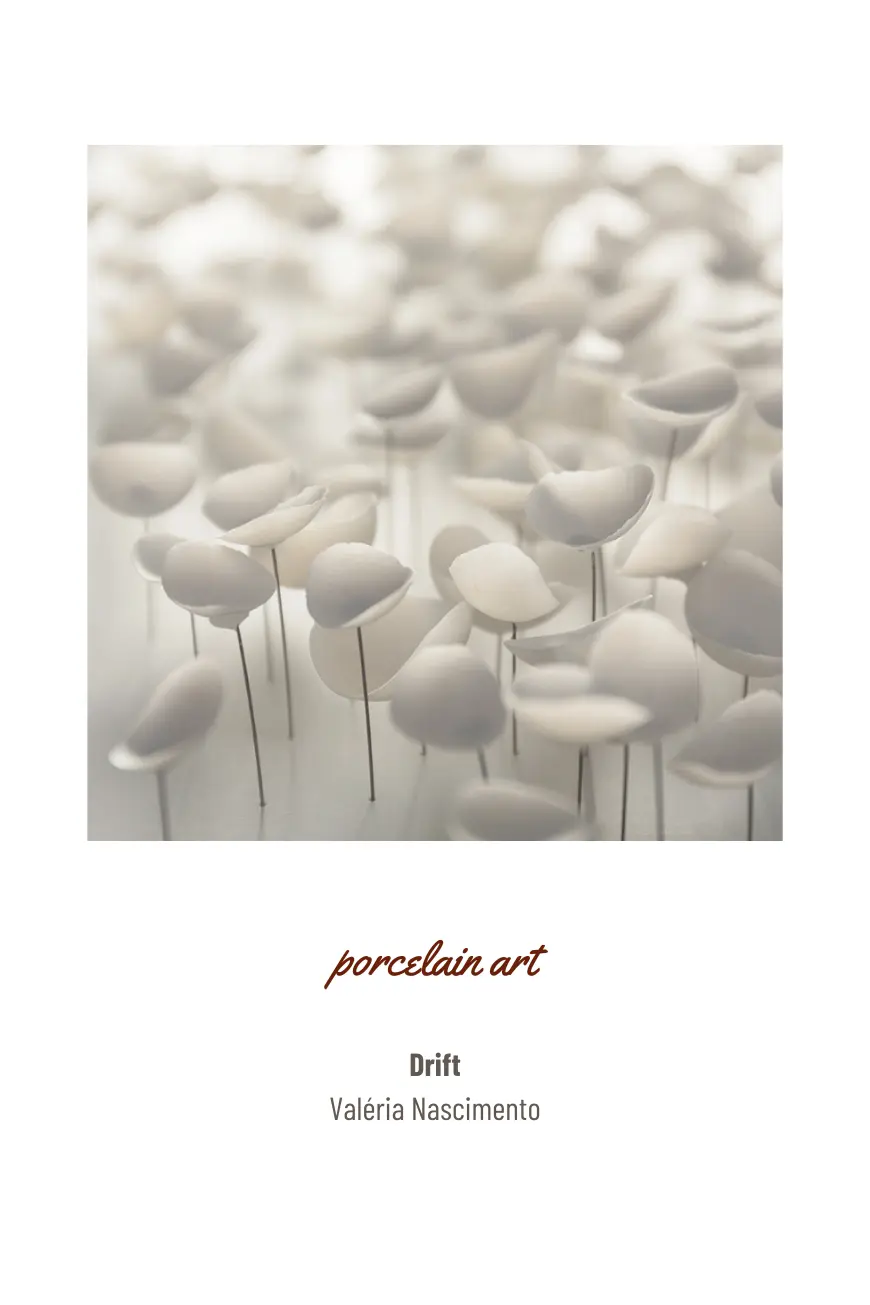

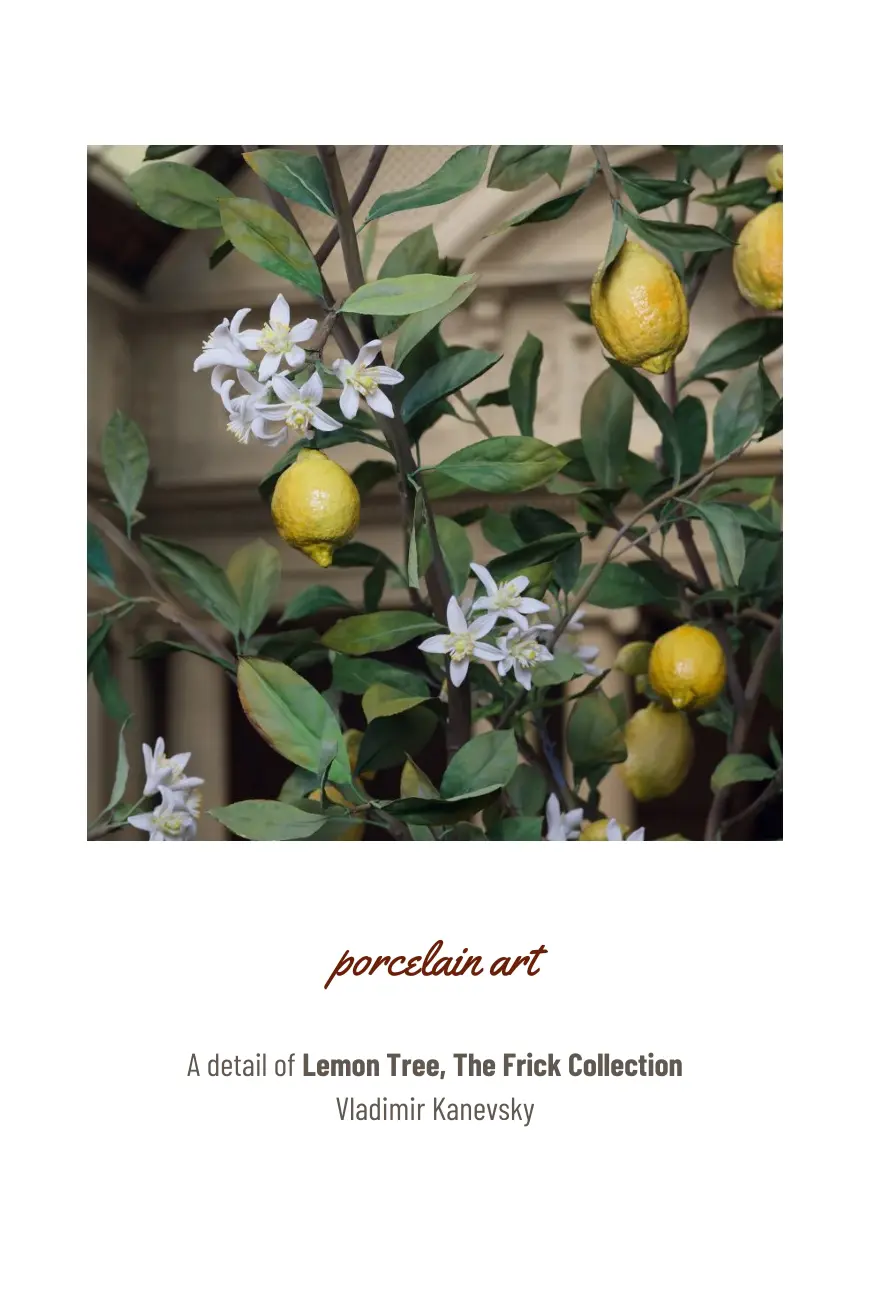

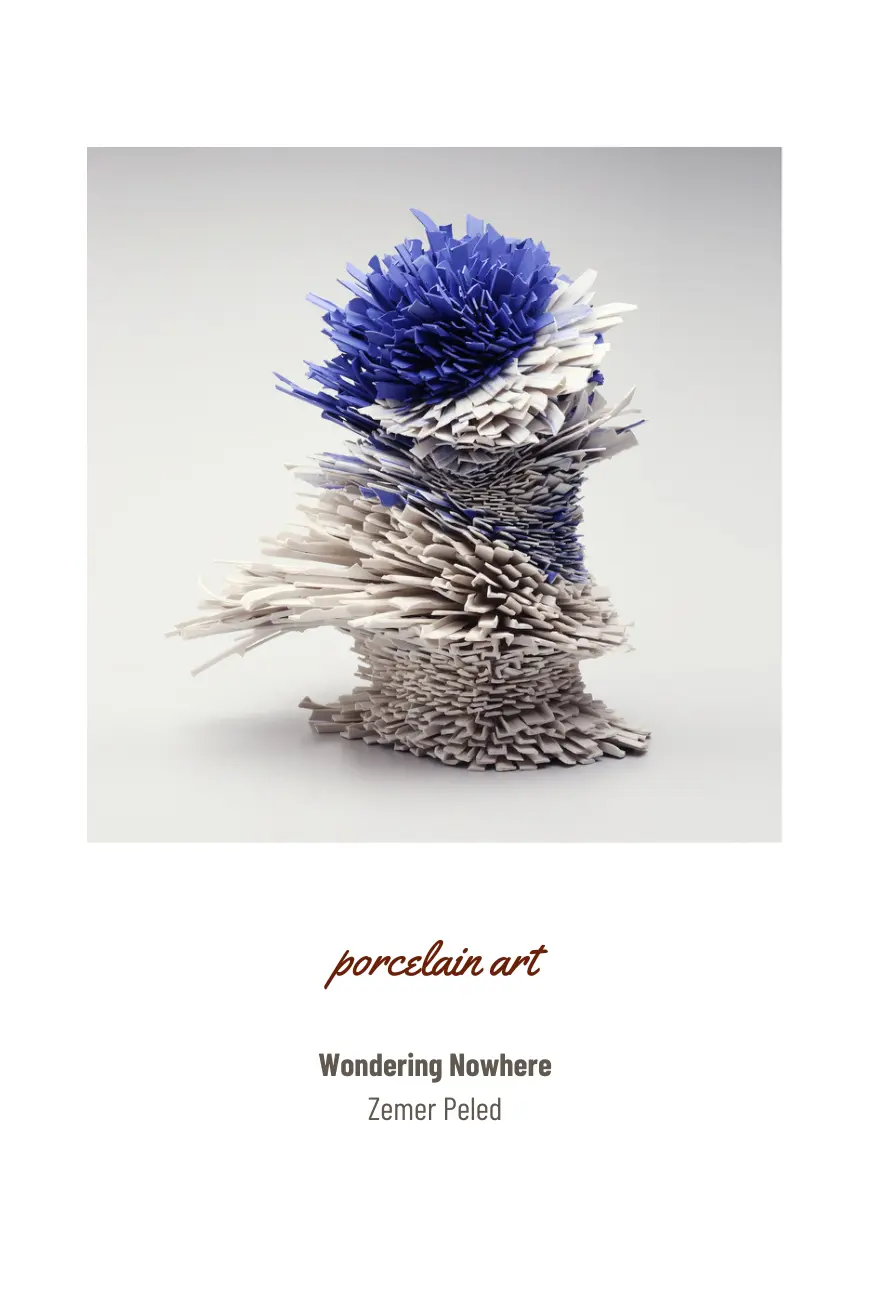

#4. Porcelain Art

Porcelain Art stands at the decorative, intricate end of the ceramic spectrum. It specifically favours precision, finesse and symbolism over function – rooted in centuries of ornamental tradition, yet continually reinterpreted by contemporary artists. Therefore, these works are rarely meant to be touched or used. They are meant to be seen.

Definition

Non-functional artworks made from porcelain, often decorative, symbolic or highly detailed.

Focus

Visual refinement, ornamentation, storytelling and technical mastery.

Typical materials

Porcelain (soft-paste or hard-paste), often combined with lustres, gold leaf, underglaze painting or modular repetition.

Typical techniques

Slip casting, handbuilding, press moulding, delicate modelling, assembly of multiple components, intricate surface finishes.

Examples

Here below some examples of delicate and impressive porcelain art from:

- Valéria Nascimento, whose modular wall pieces evoke petals, coral or seed pods, delicately repeated to form soft, organic installations

- Vladimir Kanevsky, who creates lifelike porcelain flowers with astonishing botanical precision – each petal, stem and stamen formed and painted by hand

- Zemer Peled, whose sculptural forms are composed of thousands of sharp porcelain shards: floral, explosive and unsettlingly beautiful.

#5. Architectural Ceramics

Architectural Ceramics sits at the intersection of clay and construction. It appears on walls, floors, facades and sometimes even ceilings – integrated into spaces to offer texture, rhythm, colour and permanence. In other words, it’s less about the object but more about the surface, the pattern, the environment it transforms.

Definition

Ceramic elements created to be integrated into architecture or built environments. They can either be decorative or structural, or both.

Focus

Surface design, spatial interaction, weather resistance, visual rhythm within buildings or public spaces.

Typical materials

Stoneware, terracotta, earthenware, porcelain (when used in tiles or panels), often with industrial or custom glazes.

Typical techniques

Tile-making (extrusion, pressing, slip-casting), glazing, hand-painting, mosaic assembly, modular relief work, kiln-sagged surfaces.

Examples

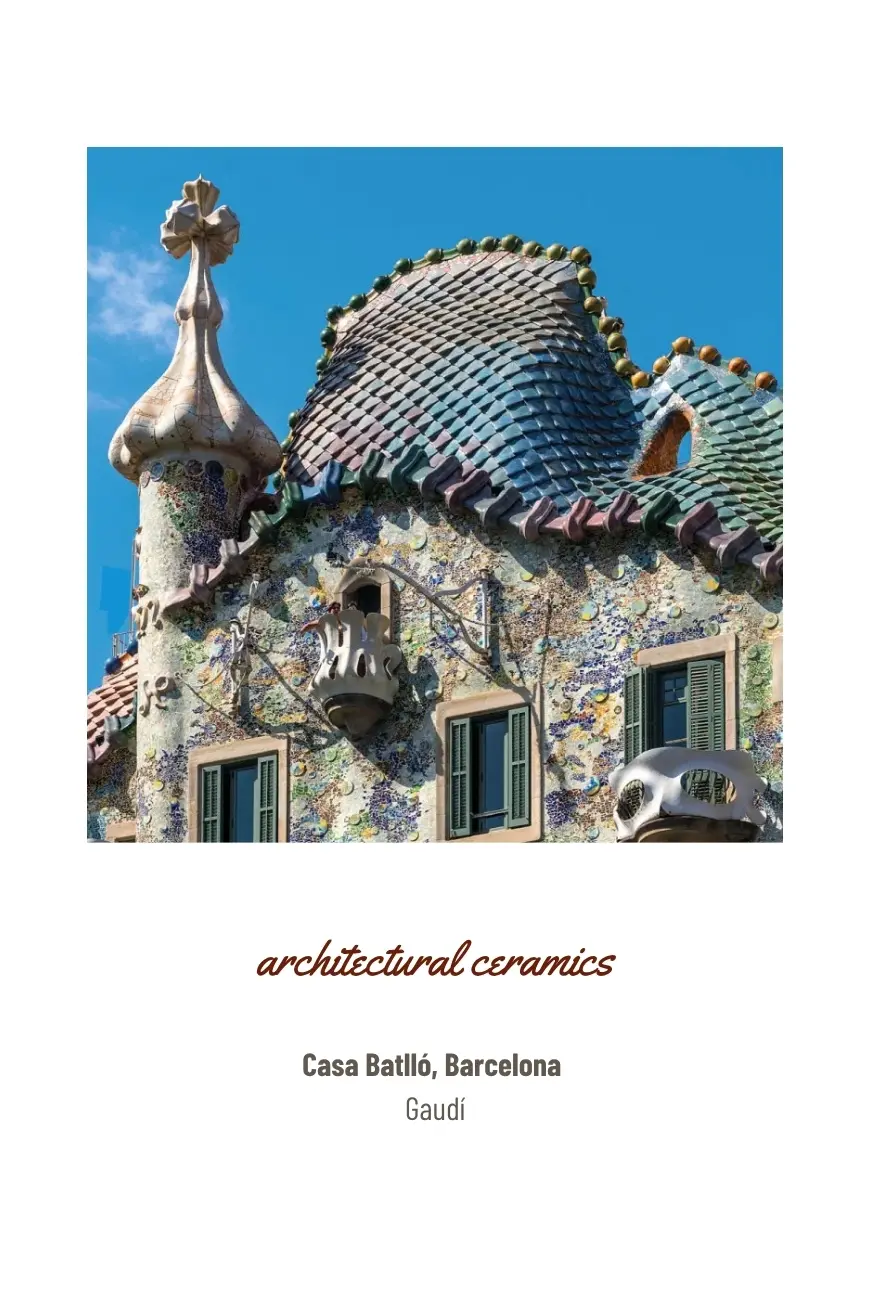

- Casa Batlló by Gaudí, where ceramic tiles, textures and reliefs blur the line between architecture and sculpture

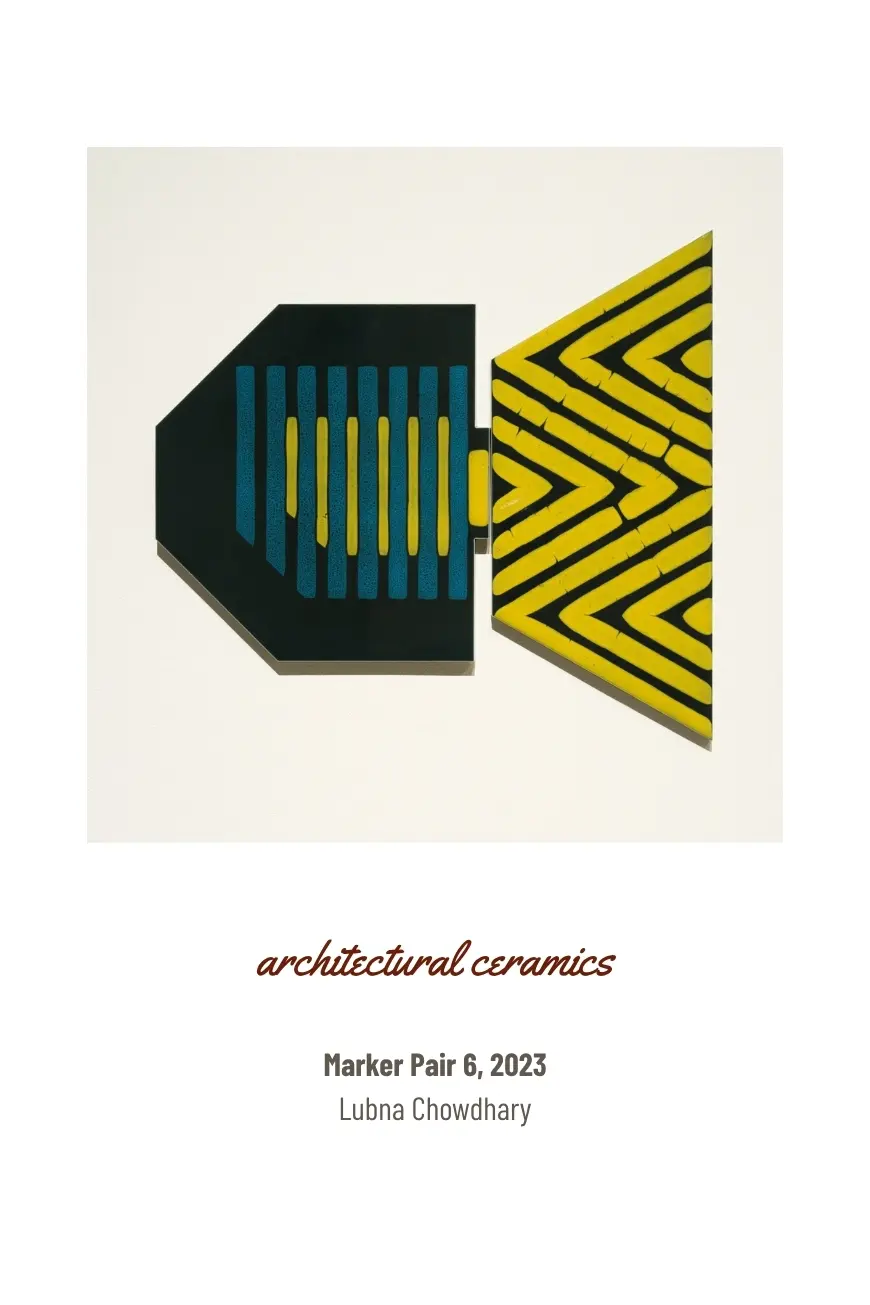

- Lubna Chowdhary, whose ceramic murals and panels bring graphic abstraction and urban rhythm to architectural spaces

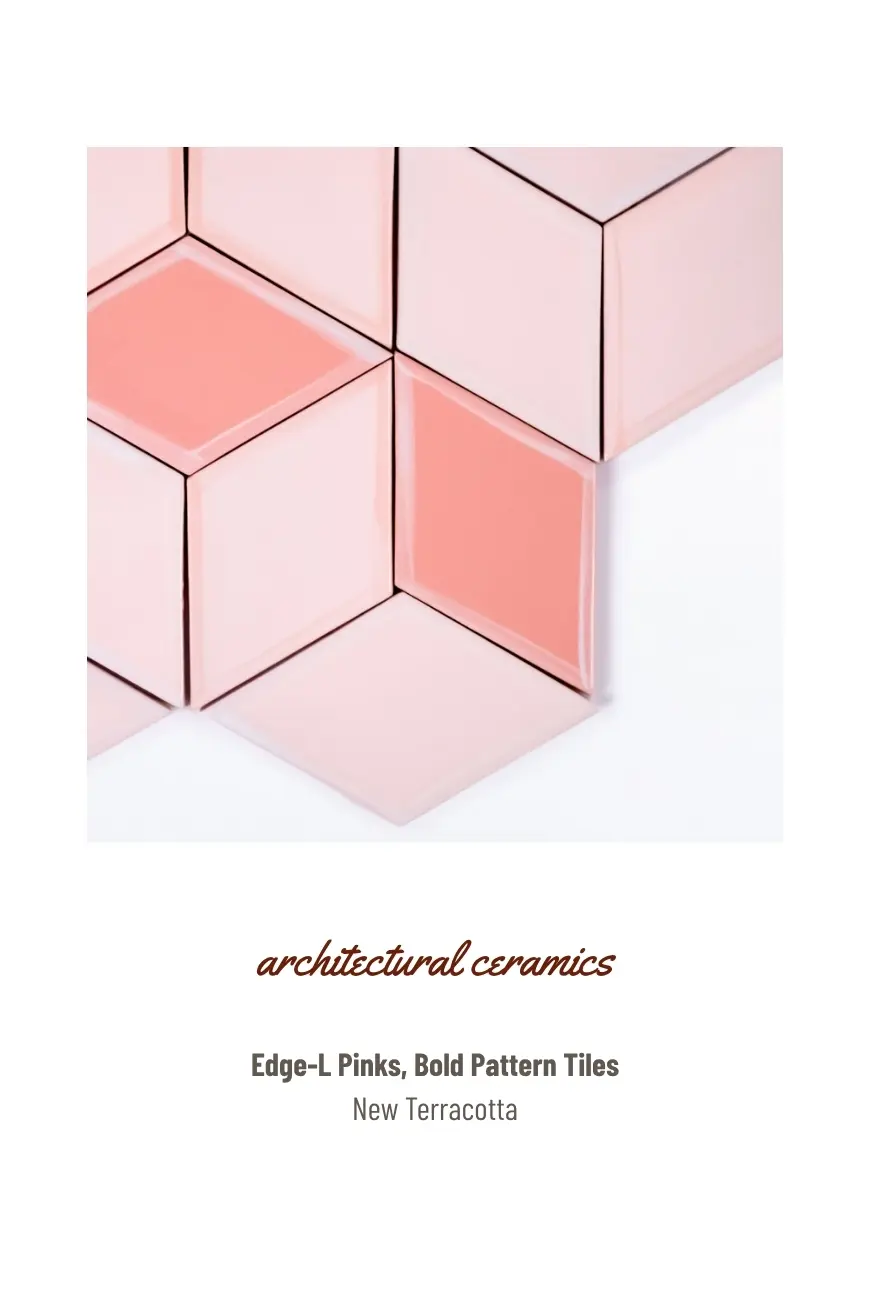

- New Terracotta, with pattern tiles like the Edge-to-Edge series combining bold geometry and tactile glazes

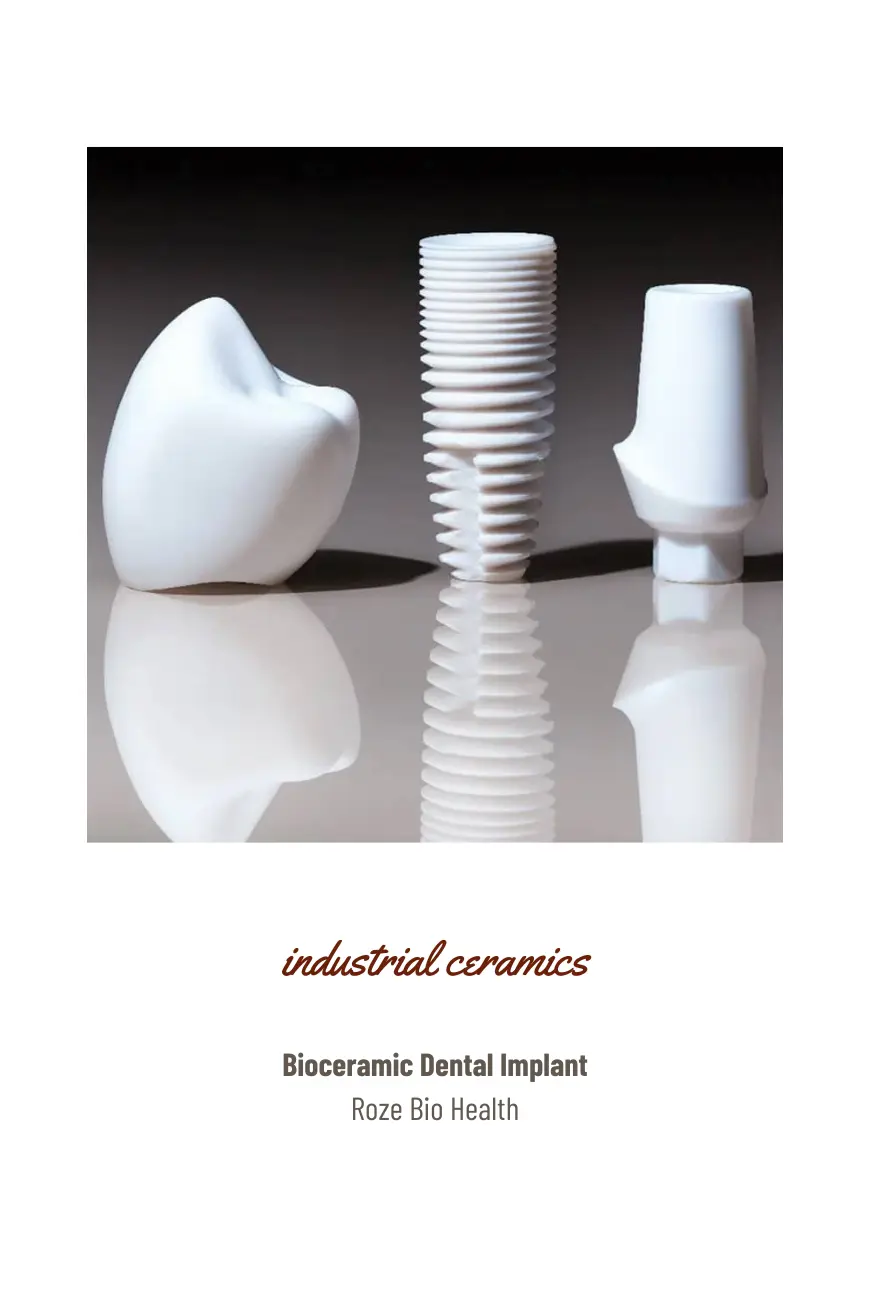

#6. Industrial Ceramics

Not all ceramics are handmade, or even seen.

Industrial Ceramics work behind the scenes: in your home appliances, car engines, medical devices, satellites. These are the quiet achievers of the ceramic world: engineered for strength, insulation, precision or biocompatibility rather than beauty.

Definition

High-performance ceramic components manufactured for industrial, scientific or medical use.

Focus

Functionality under stress: heat, pressure, abrasion, chemical exposure or bio-compatibility.

Typical materials

Alumina, zirconia, silicon carbide, steatite, barium titanate and engineered porcelain composites.

Typical techniques

Press forming, extrusion, slip casting, tape casting, sintering, machining, and metallisation.

Examples

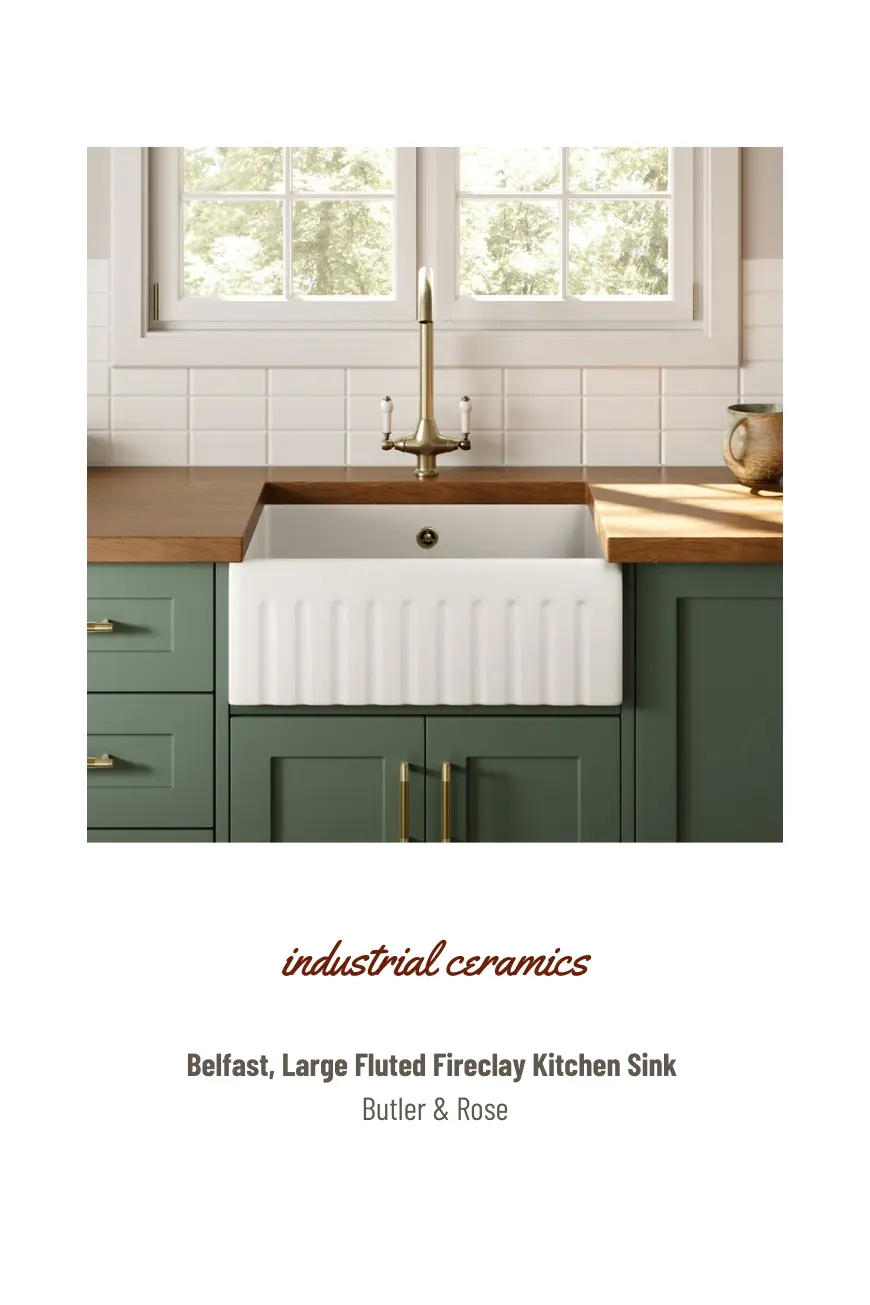

- Ceramic kitchen sinks, combining durability, chemical resistance and ease of cleaning

- Electrical insulators, used in power lines, transformers and spark plugs

- Bioceramic implants, like dental crowns and hip joint components

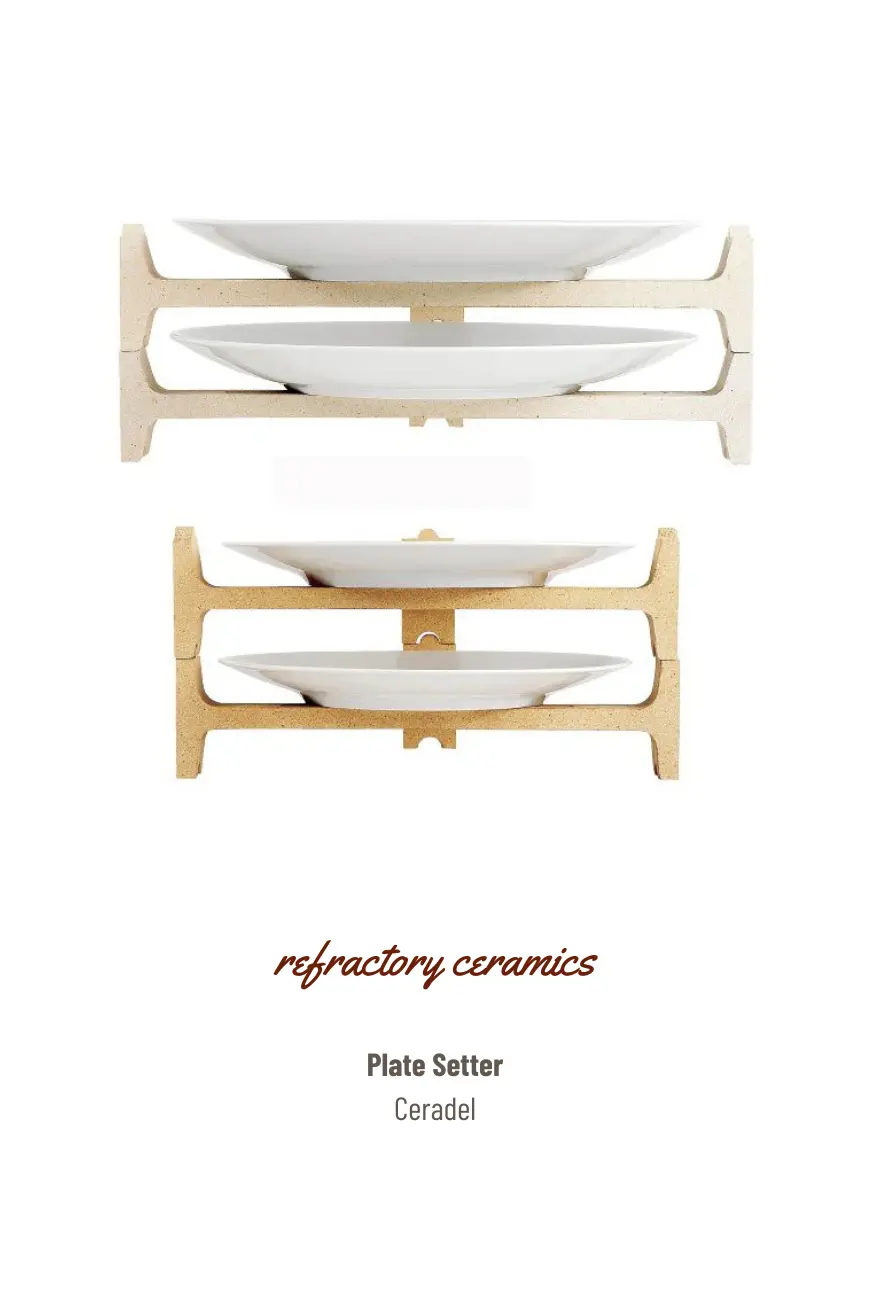

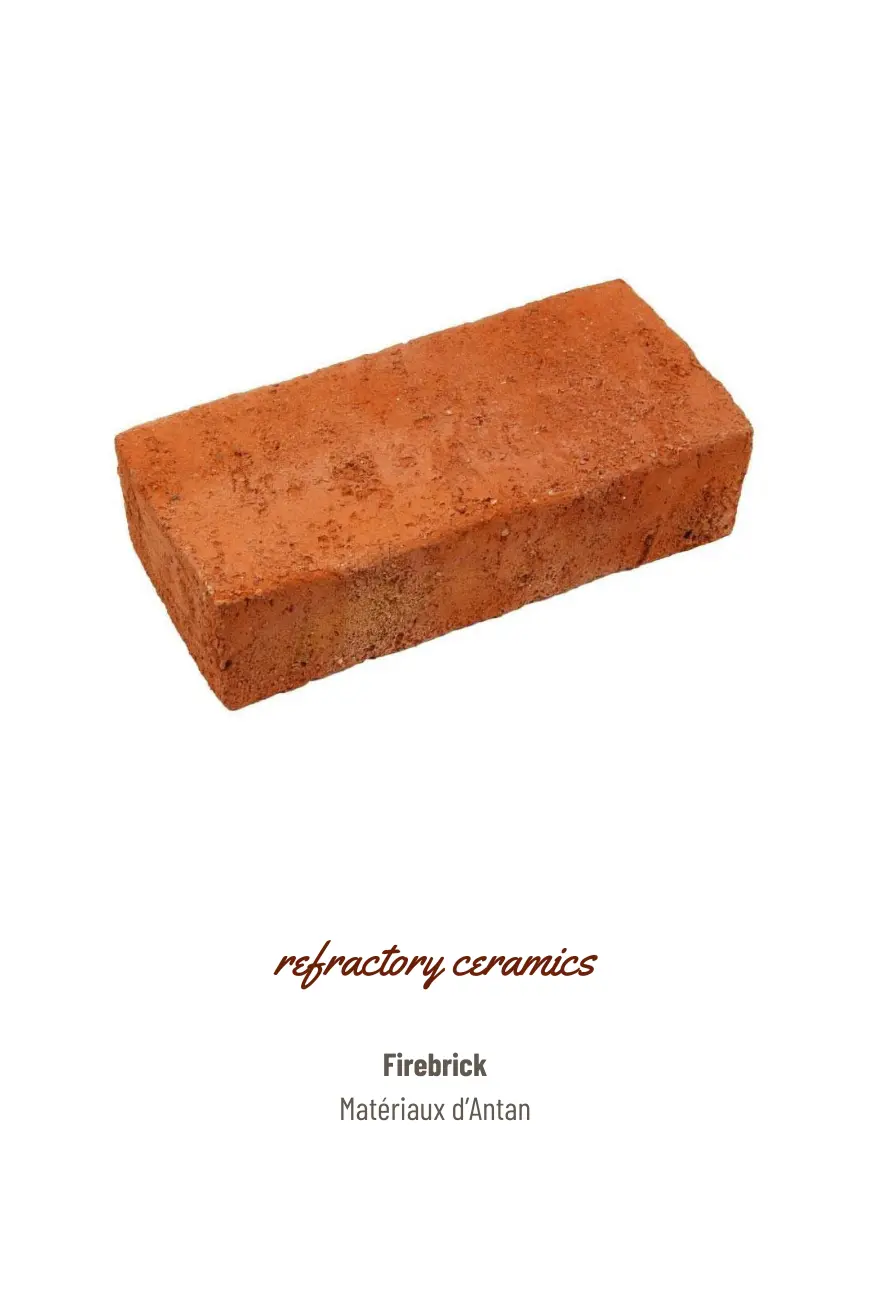

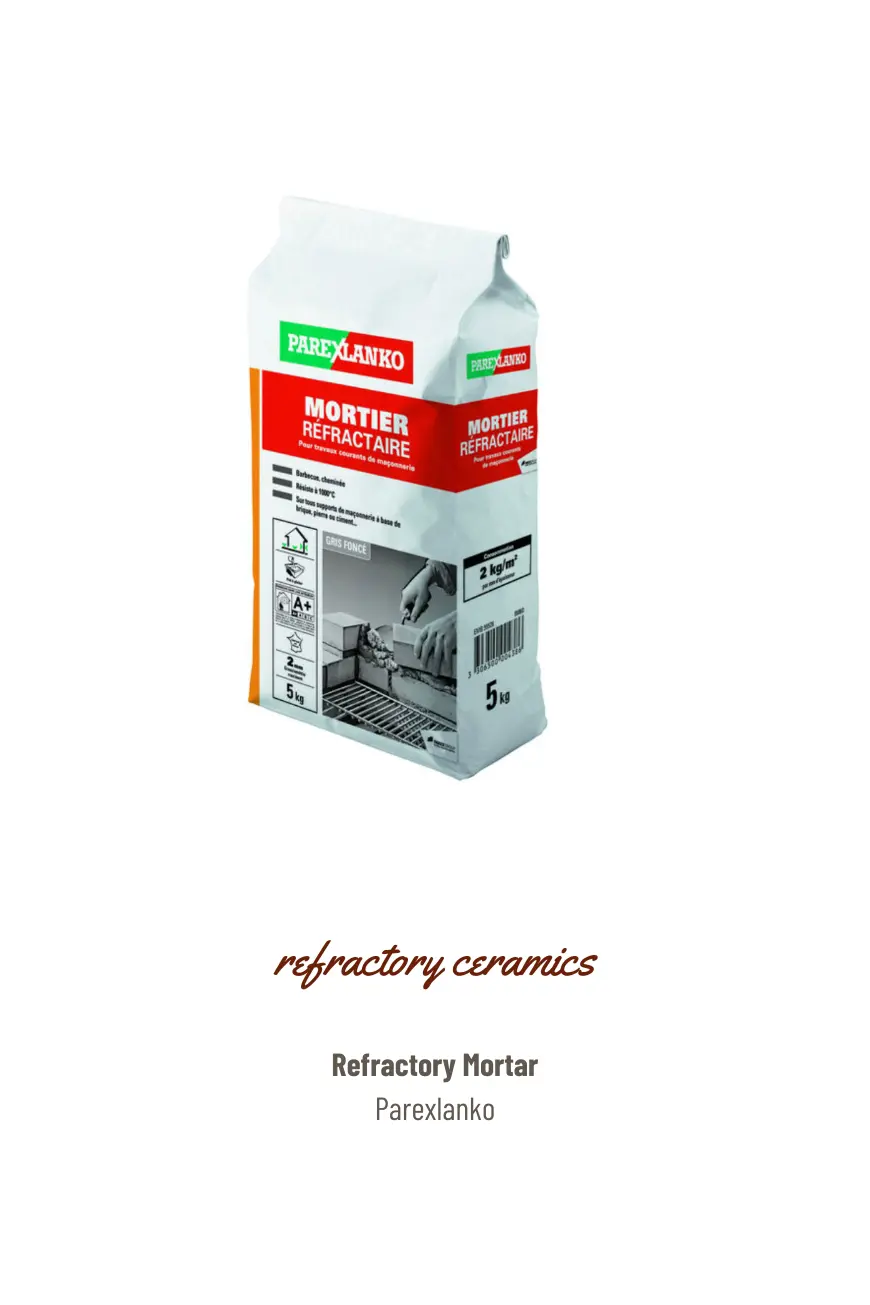

#7. Refractory Ceramics

Last but not least, Refractory Ceramics. These ceramics don’t ask to be admired. They’re built to endure.

Found in kilns, furnaces and metal foundries, refractory ceramics are engineered to withstand extreme heat, thermal shock and chemical attack. Without them, much of the ceramic world and indeed, modern industry, would quite literally melt.

Unlike industrial ceramics, which prioritise technical performance across diverse applications (from electronics to medicine), refractory ceramics specialise solely in surviving extreme thermal environments.

Definition

Ceramic materials specifically formulated to resist very high temperatures, thermal stress and corrosive environments.

Focus

Thermal endurance, structural integrity under extreme conditions, and insulation.

Typical materials

High-alumina clay, mullite, silicon carbide, zirconia, magnesia, cordierite, fireclay.

Typical techniques

Casting, pressing, extrusion, ramming, fibre-forming – often combined with binder systems and sintering.

Examples

- Kiln shelves and support posts, used during firing to hold ceramic ware

- Firebricks, lining kilns, incinerators and industrial furnaces

- Refractory mortar and castables, forming monolithic linings for smelting or steel production